Azbel Laser Cutting Welding Use 16bar 20bar N2 Gas Psa Nitrogen Generator

Description

Basic Info

| Condition | New |

| Certification | ISO, CE, CCC |

| Product Series | Psa Nitrogen Generator |

| Oxygen Capacity | 3-200m3/H |

| Oxygen Purity | 99%-99.9997% |

| After Sale Service | Yes |

| Voltage | 3 Phase-10kv/220V/380V 50Hz |

| Application 1 | Steel Factory |

| Application 2 | Chemical Factory |

| Application 3 | Metallurgy |

| Application 4 | Welding |

| Application 5 | Cutting Laser |

| Origine | Hangzhou City, Zhejiang Province, China |

| Flow | Customized |

| Nitrogen Discharge Pressure | 6 Bar |

| Installation | Skid-Mounted |

| Transport Package | Transport by Skid Mounted Bulk Cargo |

| Specification | AZN-3-AZN200 |

| Trademark | AZBEL |

| Origin | Zhejiang, China |

| HS Code | 8419609090 |

| Production Capacity | 3-200nm3/H |

Product Description

| Product Name | Cryogenic ASU |

| Output Production | GOX ,GAN, GAR, LOX, LAR , LIN |

| Oxygen Purity | ≥99.6% |

| Nitrogen Purity | 99.9997-99.9999% |

| Oxygen Capacity | 50-20000Nm3/h |

| Nitrogen Capacity | 50-40000Nm3/h |

| Warranty | 18 Months |

| Payment | TT/LC as sign |

| Design | ISO Standard ASME Standrad CE Standard |

Hello Everyone , am Zoey from AZBEL , welcome to visit AZBEL Website, glad to show you our cryogenic series ,let us know the cryogenic technology first AZBEL Cryogenic Technology

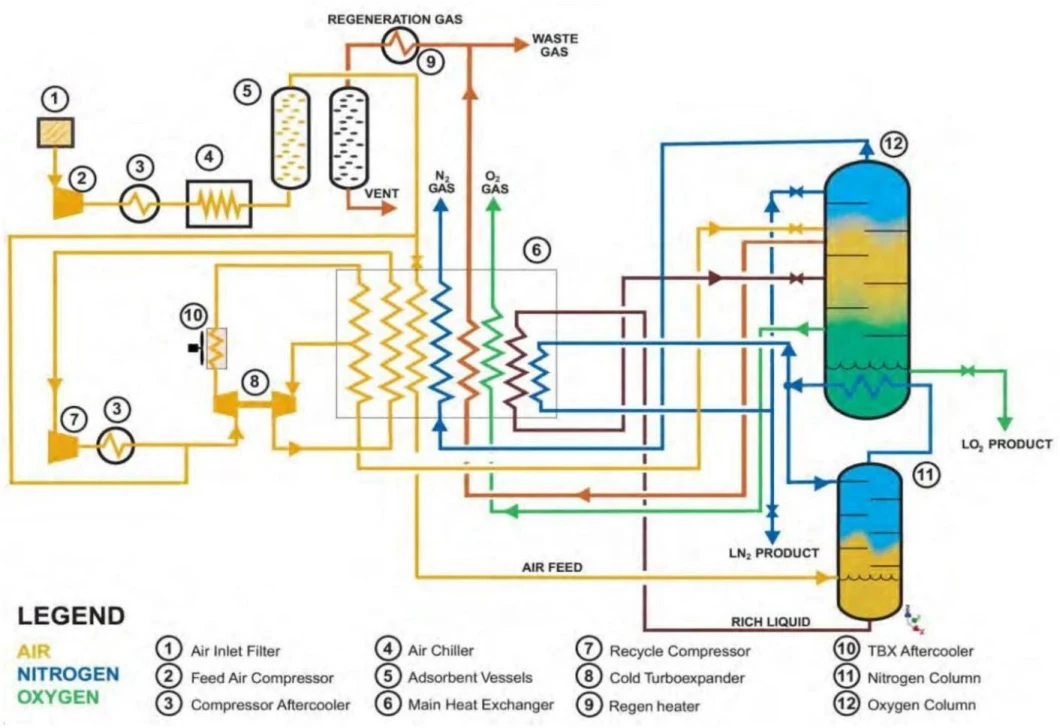

Detailed Parts Specifications MAIN AIR COMPRESSORFor the selection of air compressors, we will select according to customer needs and local conditions, centrifugal type, piston type, screw type, and subsequent cycle nitrogen compressors. PRE-COOLING UNITPreliminary cooling of compressed air to remove water AIR PURIFICATION UNITPurify impurities in gas by adsorption and catalysisIt includes an air storage tank, molecular sieve purifier I, molecular sieve purifier II and a rectification tower. Two molecular sieve purifiers are arranged side by side. One end of the two molecular sieve purifiers is connected to a heater, and the heated gas is emptied from the other end of the purifier. COLD BOX

The cold box of the air separation plant is a square or round metal structure, which is generally the highest symbol of the air separation plant. The interior of the cold box includes the main heat exchanger,the upper tower, the lower tower, the main cooling, the liquid oxygen circulation pump, the liquid oxygen delivery pump, and the valve pipeline. At the same time, pearlescent sand needs to be filled in the cold box to reduce the loss of cooling capacity EXPANDER SYSTEMBy rotating the working wheel, the gas expands and does work to generate cold energyFor the expander, we will choose gas bearings and oil bearings according to the cooling capacity Gas Booster Compressor

The oil-free gas compressor is a 100% oil-free lubrication model, and any part of the whole machine is not lubricated by lubricating oil. Products are more reliable, more economical and safer. At the same time, keep the compressed medium pure and pollution-free. The compressor adopts 7*24 hours of automatic operation, which is easy to operate and realizes automatic start and stop according to the change of pressure without unmanned control. The whole compressor is fully sealed and has no leakage. Safer and more reliable. CRYOGENIC LIQUID TANK Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes. More PhotosInstallation Instructions

Regarding our installation details, if you have needs, we will dispatch engineers to serve on site. Similarly, we also support online technical support.

Company ProfileAs one of the manufacturers, contractors, and integrators of air separation technology in China, we are based on gas separation and liquid-air separation technology to achieve clean oxygen, nitrogen, and argon with low energy consumption and high output. With the development of economy and business, the company has been involved in cryogenic air separation, PSA device, VPSA device, equipment spare parts (valve, air compressor...), LNG device and other businesses.

Quality comes from profession, ingenuity creates strength. Qiantang has been prosperous since ancient times, and we were established in 2012 by the Fuchun River. Along the way, we have gone through ups and downs and gained the joy of overcoming technical difficulties. Thanks to the national policy and economic globalization that have given us sufficient backup, let us continue to provide advanced products and professional services to global users. We cooperate with strategic partners, pursue sustainable development and attack overseas markets based on the principle of business equality and mutual benefit.

You are welcome to cooperate with us to create a better business.

Contact Person :Zoey.Gao

Hope to provide you with your dream factory through our professional services

Prev: Nitrogen Production Technologies Nitrogen Generation Unit Psa Nitrogen Gas Generator Price

Next: Air Compressor Parts Air Compressed Air Filter Element Line Filter

Our Contact