Pulse Filter Barrel Dust Remover

Overview Pulse Filter Barrel Dust Remover Product Classification: Fine Screening Series TLCM series pulse filter barrel

Description

Basic Info

| Model NO. | TLCM |

| Type | Circular |

| Function | High Frequency Vibrating Screen |

| Transmission Structure | Electromagnetic Shaker |

| Usage | Mine Shaker, Experiments Shaker, Lightweight Fine Shaker |

| Works | Rotary Vane Shaker |

| Object | Food Processing |

| Shaft Number | Single |

| Running Track | Circular Vibrating Screen |

| Supporting Device | Coil Spring |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| After-sales Service | Perfect Serivce |

| Transport Package | Wood Box |

| Specification | Customised |

| Trademark | TFZD |

| Origin | Henan Xinxiang |

| HS Code | 8474100000 |

| Production Capacity | 2000pieces/Year |

Product Description

Pulse Filter Barrel Dust RemoverProduct Classification: Fine Screening Series

TLCM series pulse filter barrel type dust remover is a new type of filtering and dedusting device, which is characterized by high purification efficiency, small size, large filtering area, good filtering effect, small pressure loss, long service life of filter cartridge, quick and convenient installation and maintenance, and continuous use.

Product Introduction

TLCM series pulse filter barrel type dust remover is a new type of filtering and dedusting device, which is characterized by high purification efficiency, small size, large filtering area, good filtering effect, small pressure loss, long service life of filter cartridge, quick and convenient installation and maintenance, and continuous use.

Structure and working principle

The TLCM series pulse bucket type dust remover is equipped with air inlet, filter cartridge, air outlet, air bag, pulse controller, blowing valve, blowing pipe, etc. The filter cartridge is folded and rolled by polyester fiber, its lower end is closed, and the upper end center is opposite to the lower end of the blowing pipe. After the dusty gas enters the dust remover from the air inlet, the air flow velocity slows down, and the coarse particles leave the air flow and settle in the dust collection room, The fine dust is blocked on the outer surface of the filter cartridge when passing through the filter cartridge with the airflow, and the clean gas is discharged from the air outlet; When the ash layer on the surface of the filter cartridge is thick, the pulse controller sends a command to open the injection valve, and the compressed air in the air bag is ejected at a high speed through the injection pipe. At the same time, it induces several times of the amount of injected air into the filter cartridge, and ejects rapidly from the inside to the outside. The dust on the outer surface of the filter cartridge is blown down into the dust collection chamber, and then discharged from the ash hopper. Pulse injection method is adopted for dust removal of the dust remover, which can completely remove dust without damaging the filter cartridge, so as to ensure the service life of the filter cartridge. The ash cleaning process is automatically controlled by the pulse controller, and pressure difference control or time control can be adopted.Technical Characteristics

1. The deduster has high dedusting efficiency, good filtering effect, small size and stable operation.

2. The filter cartridge is installed by skeleton, with good sealing performance and is firm and reliable.

3. The filter cartridge has a long service life and is easy to install and maintain.

4. The box is designed with good air tightness. The inspection door is made of excellent sealing materials with low air leakage rate.

5. The inlet and outlet air ducts are arranged compactly with small air flow resistance.

Scope of Application

It is widely applicable to the purification of dust containing gas and the recovery of dust materials in the food, pharmaceutical, feed, metallurgy, building materials, cement, machinery, chemical industry, electric power and light industry.

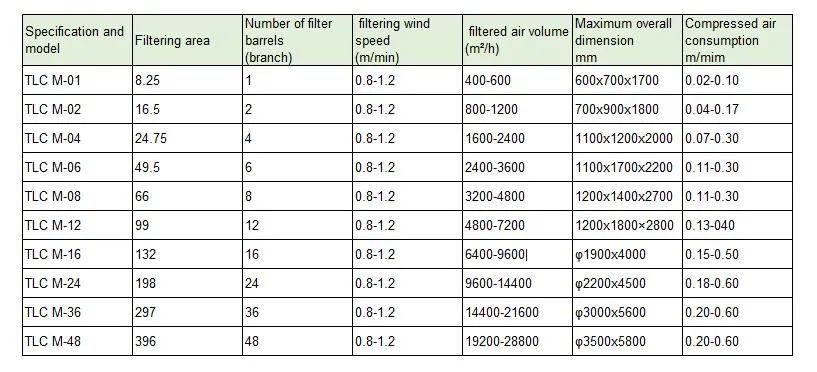

Technical Parameter

Applicable industries

Chemical industry: resin powder, pigment, washing powder, micro powder, paint, soda ash, lemon powder, rubber, plastic, etc.

Abrasives, ceramic industry: alumina, quartz sand, mud, sprayed soil particles, etc.

Food industry: sugar, salt, alkali, monosodium glutamate, milk powder, soy milk, yeast, fruit juice, soy sauce, vinegar, etc.

Paper industry: coating paint, clay mud, black and white liquid, waste liquid, papermaking liquid, wastewater recycling, etc.

Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, electrode powder, etc.

Pharmaceutical industry: Chinese medicine powder, Chinese medicine liquid, Western medicine powder, Western medicine liquid, Chinese and Western medicine granules, etc.

Environmental protection: garbage, human and animal excrement, and urine, waste oil, food wastewater, wastewater processing, etc.

Processing process Production workshopThis is our inner workhouse.

some small equipment or parts will be made from here.

There are cranes, laser cutting machines, electric welding machines, platen machines, angle grinders, polishing machines, forklifts, and other equipment. Here is our outdoor operation platform.

We often produce and assemble large machines here.

There are electric welding machines, polishing machines, large cranes, and forklifts.Packaging & ShippingAfter you place the order and pay the deposit, we will start to arrange the production and contact the ocean freight transportation agency to reserve the position. Two days before the end of production, you need to complete the final payment. Then, we inform the ocean cargo transportation agent company that it is ready to come to the factory to pull the goods to the port. On the day of delivery, we will send the customer the factory video and pictures, and mark the corresponding English name of each product and product parts with a marker to prevent the customer from not knowing what each part is after receiving the goods. At the same time, we will put the English version of the product instructions in the cargo box. We generally select freight forwarders with preferential prices for customers to deliver goods for you. The shipping method can be FOB or CIF. You can also choose EXW, and then contact the goods agent company yourself.Customer visit

FAQ

1. Who are we?

Our headquarters is located in Henan, China, and our factory was established in 2002. At present, there are more than 100 workers, technical engineers, foreign trade sales personnel, and administrative personnel. The factory covers an area of more than 2000 square kilometers and is mainly engaged in vibrating screening and conveying and feeding equipment.

2. How do we guarantee quality?

Always provide pre-production samples before mass production; Always carry out a final inspection before shipment.

3. What can you buy from us?

You can purchase a vibrating screen, roller screens, rotary screens, vacuum conveyors, mixer, and customized vibrating machinery and conveying equipment in our factory.

4. What are our strengths?

As one of the old enterprises in the screening industry, Tianfeng has provided a large number of screening equipment and systems at home and abroad. Mass production, rapid delivery, stable quality, affordable price, and excellent after-sales service have become the symbols of Tianfeng.

5. What services can we provide?

Accepted delivery conditions: FOB, CFR, CIF, EXW, CIP, FCA, CPT, DDP, express;

Accepted payment currency: USD, EUR, RMB;

Type of payment accepted: telegraphic transfer, letter of credit, express remittance, credit card, PayPal, Western Union remittance, cash, custody;

Oral: English, Chinese, French.

6. What information do we need to help you choose a perfect machine?

-Name and characteristics of raw materials.

-Purpose of use: remove impurities, filter, and grade.

-Processing capacity: kg/h, L/h.

-Raw material size: (mesh or mm).

-How many floors do you need?

-Voltage, frequency, phase (single-phase or three-phase) Note: You'd better send us the relevant pictures or materials you want to filter, which can ensure that we recommend the appropriate machine for you.

Our Contact

Send now