Zydh Disc Oil Water Separator Centrifuge Coconut Oil Separator

Description

Basic Info

| Model NO. | ZYDH270 |

| After-sales Service | 1year |

| Warranty | 1year |

| Type | Centrifuge |

| Object | Milk Cream |

| Separation Mode | Sedimentation Type |

| Operating Type | Continuous Type |

| Installation | Vertical |

| Centrifuge Type | Disc Centrifuge |

| Distillation Equipment Type | Separation Equipment |

| Extraction Tower Type | Turntable Tower |

| Pressure | Low Pressure |

| Condition | New |

| Operation | Automatical Continuous |

| Impurity | Less Than 2ppm |

| Control Box | Can Be Customize |

| Raw Material | 304/316L Food Grade |

| Bearing | SKF Bearing |

| Separation Phase | Two/Three Phase |

| Cream% | Adjustable According to The Requirment |

| Transport Package | Wooden Case |

| Specification | depend on model |

| Trademark | FIVEMEN |

| Origin | Jiangsu, China |

| HS Code | 8421192000 |

| Production Capacity | 50-200L/H |

Product Description

Appication

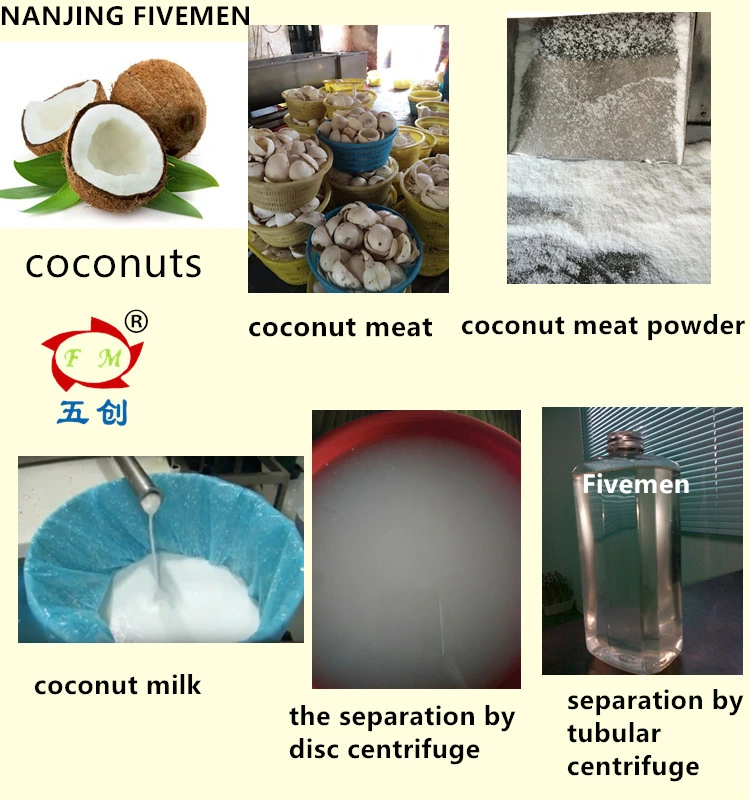

Plant oil CENTRIFUGE separator is the main equipment for a vegetable oil continuous refining system,

can be used for plant oil refining,continuous degreasing, dephosphorization, de-soap,

dehydration and other procedures.

Reducing the harmful ingredients in vegetable oil, to meet national standards.

For the coconut oil/ soybean oil / palm oil, we have exported to many countries.

and have the working video of the separation.

Features

1. High Speed and high separation factor

2.running balance

3.simple operation

4.low oil consumption.

5. Automatically discharging

6. continuous operation.

7. All the key parts of the machine bearing all use imported bearing((brand SKF)

8.Drum adopts 0Cr13Ni4Mo material that is steel high purity, good performance.

9. In order to meet different requirements of production scale, the machine adopt bottom washing. Facilitate liquid seal and exclusive soap, the heart pump discharge the material, reducing system

operating pressure. Regulate different specific gravity ring, can be suitable for all kinds of oil, so that

better separation.

Working Principle

Zydh oil centrifuge separator can separate rapid succession of solid liquid and liquid liquid ,which is a kind of vertical centrifuge.

A rotary drum is install in the upper end of vertical shaft, the driving device driven by a motor to rotate

at high speed. Drum have a set of a butterfly shaped parts mutually overlapped together.

Have a very small space left between the disc and disc. Suspension pour intodrum by feeding tube

which is located center of the drum.When the slurry flows past the clearance between the disc, solid particles in centrifuge sinking to the sediment is formed on the disc. Sediment falls of the disc along

the sliding surface of the disc and accumulate in the drum at the largest diameter.

The separation of the liquid exhaust drum from the liquid outlet .The function of the disc is to short

the distance between the settlement of solid particles or liquid droplets and to expand the area of settlement of the drum.Because the installation disc in the drum and greatly improves the separators' production capacity.

Technical parameters

Model | Capacity (L/h) | Basket Diameter (mm) | Rotation Rate of Drum (r/m) | Separation factor | Power (KW) | Weight (kg) | Dimension (mm*mm*mm) |

ZYDH270 | 2000 | 270 | 7200 | 6950 | 4 | 550 | 865*645*1100 |

ZYDH315 | 3000 | 315 | 6500 | 7000 | 5.5 | 650 | 900*600*1150 |

ZYDH385 | 4000 | 385 | 6500 | 7500 | 7.5 | 750 | 1100*1050*1250 |

ZYDH430 | 5000 | 430 | 6000 | 8050 | 11 | 900 | 1200*950*1400 |

ZYDH470 | 8000 | 470 | 5800 | 8500 | 18.5 | 1100 | 1250*1000*1550 |

High speed disc centrifuge

| Model | speed/rpm | separation factor | weight |

FMDB190 | 10600 | 10000 | 300 |

FMDB230 | 9600 | 11800 | 450 |

FMDB355 | 7800 | 12000 | 620 |

Application

| Packing & Shipping |

Our Services |

Pre-Service

1. 24 hours onlinne consult and service

2. Introduce the details of products to the customers, answer the question raised by customer at firstly;

3. Providing the operation , installation and working video for customers.

4. Providing the different solutions for choice according to the needs and requirements of customers;

Sale Service

1. Ensure new product with high quality before delivery;

2. Packing according to the export requirements and shiping carefully;

3. Provide full set of documents as customer's requirements.

4. Providing one year sparing parts for you for free.

5. Delivery on time

After-sale Service

1. Help to install and debug the equipment, Our technicians could be dispatched for

overseas service.

2. Provide 24 hours techincal support by e-mail or phone;

3. Abundant spare parts in stock are available to provide.

4. Help customers slove any other questions about products or other aspect;

5. Your workers could get trained both in our factory and yours.

Service Commitment

1. We will provide one-year warrantee to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.2. Consultant services for whole machine life, 24 hours technical support by email and telephone.3. Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

| Company Information |

Prev: Refrigerated Air Cool Compressed Air Dryer

Next: Small Dehumidifier Low Noise Energy Saving Dryer Industrial Compressed Air Dehumidifier

Our Contact